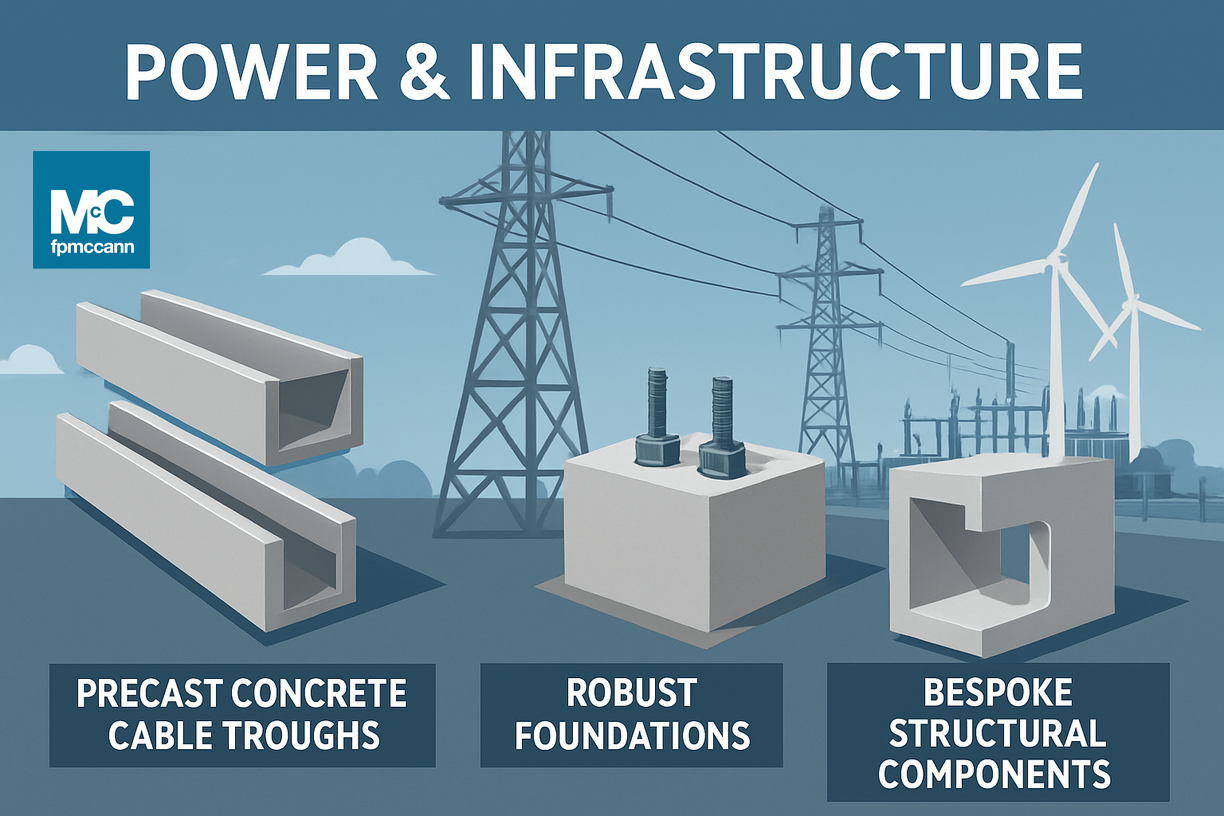

Powering Progress: Why FP McCann’s Precast Concrete Solutions Lead the Infrastructure Sector

In the rapidly evolving landscape of power and infrastructure development, the demand for robust, reliable, and sustainable solutions has never been greater. From safeguarding critical electrical cables to supporting renewable energy installations, the foundational components of our national infrastructure must withstand immense pressures, both environmental and operational. FP McCann stands at the forefront of this challenge, offering a comprehensive range of precast concrete Power & Infrastructure products that consistently outperform alternatives, ensuring longevity, efficiency, and unparalleled reliability.

The Unrivalled Strength of Precast Concrete in Infrastructure

Precast concrete, by its very nature, offers inherent advantages that make it an ideal material for power and infrastructure applications. Manufactured in controlled factory environments, these products benefit from stringent quality control, precise engineering, and optimal curing conditions. This results in components with superior strength, durability, and a consistent finish that is difficult to achieve with in-situ methods.

FP McCann leverages these inherent benefits, combining them with decades of industry expertise to produce a range of solutions tailored to the rigorous demands of the power sector. Our products are designed not just to meet, but to exceed, the performance expectations of critical infrastructure projects across the UK.

Key Product Areas and Their Advantages

FP McCann’s Power & Infrastructure portfolio encompasses a variety of essential components, each engineered for specific applications and offering distinct advantages over traditional or alternative materials:

- Electrical Cable Troughing Systems

Cable troughing is a cornerstone of modern infrastructure, providing vital protection and accessibility for power and communication cables. FP McCann offers a specialist range of precast reinforced concrete cable troughs and ducting systems, including straight units, corner, angled, and tee units, as well as bespoke solutions.

Advantages over Alternatives (e.g., GRP, HDPE):

While lightweight alternatives like Glass Reinforced Plastic (GRP) and High-Density Polyethene (HDPE) troughs have emerged, precast concrete maintains significant advantages, particularly in critical applications:

- Superior Durability and Longevity: Concrete troughs are inherently more robust and resistant to environmental degradation, UV radiation, and chemical attack than plastic alternatives. They do not degrade over time due to exposure to sunlight or temperature fluctuations, ensuring a much longer service life with minimal maintenance.

- Higher Load-Bearing Capacity: Precast concrete troughs, especially those rated to BS EN 124 standards, offer significantly higher load-bearing capacities, making them suitable for heavy traffic areas, industrial zones, and locations where accidental heavy loads might occur. While some GRP systems claim high ratings, the inherent rigidity and compressive strength of concrete provide a more reliable long-term solution for heavy-duty applications.

- Enhanced Security and Vandalism Resistance: The substantial weight and robust nature of concrete troughs make them far more resistant to theft and vandalism compared to lightweight plastic or composite alternatives. This is a critical factor in protecting valuable and sensitive underground infrastructure.

- Fire Resistance: Concrete is non-combustible, providing inherent fire resistance that is crucial for protecting vital electrical cables. In contrast, while some GRP and HDPE systems are fire-retardant, they are still combustible and can contribute to fire load in extreme conditions.

- Thermal Stability: Concrete provides excellent thermal mass, helping to regulate the temperature of the enclosed cables, which can be beneficial for cable performance and longevity.

- Cost-Effectiveness in the Long Run: While the initial cost of lightweight alternatives might sometimes appear lower, the superior durability, minimal maintenance requirements, and extended lifespan of precast concrete often result in a lower total cost of ownership over the project’s lifecycle.

- Precast Concrete Foundations and Transformer Bases

Critical infrastructure, such as electrical substations and renewable energy installations, relies on stable and durable foundations. FP McCann provides precision-engineered precast concrete foundations and transformer bases, offering a rapid, reliable, and cost-effective alternative to in-situ concrete pours.

Advantages over In-Situ Concrete:

- Speed of Installation: Precast foundations are manufactured off-site and delivered ready for immediate placement, drastically reducing on-site construction time, labour costs, and project delays due to weather. This is particularly beneficial for large-scale infrastructure projects with tight deadlines.

- Superior Quality Control: Factory production allows for strict quality control measures, ensuring consistent concrete strength, precise dimensions, and a high-quality finish that is often challenging to achieve with on-site pouring, especially in varying weather conditions.

- Reduced Site Disruption: Off-site manufacturing minimises on-site activities, reducing noise, waste, and traffic disruption, which is crucial for projects in sensitive or urban environments.

- Environmental Benefits: Precast production can lead to less waste, more efficient use of materials, and reduced carbon emissions compared to traditional cast-in-place methods, contributing to overall project sustainability.

- Enhanced Durability: The controlled curing environment of precast concrete leads to a denser, more durable product with improved resistance to chemical attack and freeze-thaw cycles, ensuring a longer service life for critical infrastructure.

- Bespoke Structural Components and Pit Solutions

Many power and infrastructure projects require unique, tailor-made solutions. FP McCann excels in providing bespoke precast concrete structural components, communication boxes, firewalls, and pit solutions, precisely engineered to meet specific project requirements.

Advantages of Bespoke Precast over Fabricated Steel or In-Situ Alternatives:

- Design Flexibility and Precision: Precast concrete can be moulded into virtually any shape or size, offering unparalleled design flexibility while maintaining precise dimensions and tolerances, crucial for complex infrastructure elements.

- Integrated Features: Bespoke precast components can incorporate features such as cast-in channels, inserts, and openings during manufacturing, thereby reducing on-site work and potential errors.

- Corrosion Resistance: Unlike steel, concrete does not corrode, making it ideal for underground or exposed environments where moisture and aggressive chemicals are present. This significantly reduces long-term maintenance costs.

- Fire Resistance: As a non-combustible material, concrete provides inherent fire resistance, a critical safety feature for infrastructure components that may house sensitive equipment or cables.

- Speed and Efficiency: Even for bespoke items, the precast manufacturing process allows for faster production and installation compared to complex in-situ pours or intricate steel fabrication on-site.

FP McCann: Your Trusted Partner in Power & Infrastructure

FP McCann’s commitment to the power and infrastructure sector is underpinned by extensive industry experience, technical expertise, and a relentless focus on quality and innovation. As an Achilles Utility Vendor Database (UVDB) approved supplier, we adhere to the highest standards of compliance and environmental responsibility [1].

By choosing FP McCann, you are partnering with a leader dedicated to delivering solutions that are not only robust and reliable but also contribute to the long-term efficiency and sustainability of our national infrastructure. Our tailored approach ensures that whether your project involves renewable energy, electrical substations, or complex cable management, we have the precast concrete solution to power your progress.

Explore our full range of Power & Infrastructure solutions and discover how FP McCann can add value to your next project: https://fpmccann.co.uk/uk/power-infrastructure/

Visit the FP McCann website for more information on Powering Progress: Why FP McCann’s Precast Concrete Solutions Lead the Infrastructure Sector